A Deep Dive into Mineral Processing Equipment

Mineral processing equipment is indispensable in the mining industry, playing a pivotal role in the extraction and refinement of valuable minerals from ore deposits. This equipment encompasses a diverse range of machinery and technologies that optimize the recovery of valuable minerals while minimizing waste and environmental impact. The process begins with ore preparation, where raw ore is crushed and ground into smaller particles, making subsequent processing steps more efficient. Physical separation and concentration methods are used for the extraction of the mineral from the gangue with methods including gravity concentration, flotation and magnetic concentration. This is followed by dewatering and moisture control equipment that help in elimination of moisture leaving the final product dry in order to be transported and further processed. Environmental management means that the potential impact of mining operations to the environment is kept to a minimum and entails a management system on conservation of natural resources, waste disposal among other issues. Sophisticated automation and controls systems have boosted how mining processes could be optimally managed through real-time observation and analysis for improvement of decision making and the general running of the mines. At last, employing the principles of occupational health and safety, the security and safeguard of workers are respected by implantation of safeties as well as procedures in the formation as well as usage of mineral processing tools. As a critical system, these elements combine to improve the economic effectiveness, environmentally friendly, anti-hazard nature of mining processes.

The Importance of Mineral Processing Equipment

Mineral processing equipment plays a crucial role in maximizing resource utilization, enhancing product quality, increasing efficiency and productivity, promoting environmental sustainability, ensuring safety and reliability, facilitating downstream processes, and fostering economic development. Its significance spans the entire mining value chain, from ore extraction to the production of refined products. Mineral processing involves a variety of techniques aimed at separating valuable minerals from waste rock. This process relies heavily on specialized equipment tailored to the characteristics of the minerals involved. Key components of mineral processing equipment include:

1. Crushers and Grinders

2. Screens and Classifiers

Screens and classifiers play a crucial role in mineral processing by separating particles based on size, facilitating the classification of ore particles and the removal of oversized or undersized material.

Screens consist of surface openings with specific sizes to allow particles of desired sizes to pass through while retaining larger or smaller particles. They are critical in either early or later stages of the screening process depending on the objective of the practice to improved performance by sieving large quantities of materials into respective categories. There are two types of screens, each entirely dependent on the raw materials used. Wet screens employ spray nozzles and water along with screen vibration during the sorting process, while dry screens rely solely on vibration.

Whereas, classifiers employ sedimentation theory and differential settling velocities to sort out particles based on a size and density. More often, water is the fluid medium through which classifiers attain the function of segregating fine particles from the larger ones, so as to achieve the appropriate particle size range for subsequent processing. Modern developments in the field of a screen and a classifier are aimed at increasing the throughput rate of the equipment, limiting its service requirements, and, ultimately, increasing the efficiency of the classification process. Classifiers can be divided into two distinct categories according to the technology they use. Air classifiers separate materials using a dry process, whereas hydrocyclones sort particles in a liquid suspension.

There have been progressive enhancements on screens and other parts of a disperser that increase the capacity of the screen and its resistance to harsh working environment. Modern classifiers have an improved flow pattern and parameters that can be modified in order to accomplish the correct particle separation. Furthermore, programmable control also makes it possible for changes to be made in real-time thus improving on the general outcomes as well as ensuring standardization of operations.

3. Gravity Separation Equipment

4. Magnetic Separators

5. Flotation Machines

6. Thickeners and Clarifiers

7. Filters and Dewatering Equipment

Crushers and grinders are used for breaking down large chunks of ore into smaller, more manageable pieces. This initial size reduction enables easier handling of the material throughout subsequent processing stages such as grinding and flotation.

Crushers rely on mechanical forces to crush the ore and are characterized by the method that is used to break the ore into smaller pieces; these are the compression which includes the jaw crushers and cone crusher, and Impact including the vertical shaft impact crushers. These machines exert forces on the ore or materials so as to make it to break into finer particles for other processes. Grinders, on the other hand, are employed for fine and small particle size reduction tasks that are generally done after the coarse crushing of materials. Their working principles entail the use of two surfaces, for instance rollers or a drum that turns as it grinds the materials causing further reduction in size and separation of minerals from gangue materials. Commonly used grinding equipment include ball mills, rod mills, and autogenous grinders.

Recent advancements in crusher and grinder technology focus on improving efficiency and reducing energy consumption. Some are advanced designs that improve on the efficiency of operations as well as the particle reduction parameters of crushing as well as grinding. Other control systems have also been incorporated to view the processes parameters and optimize them in real time so that efficiency is maintained and system downtimes reduced. Such machines are crucial in contemporary processes of mineral beneficiation, as they facilitate further efficient ore processing by presenting the material to the subsequent stages of beneficiation.

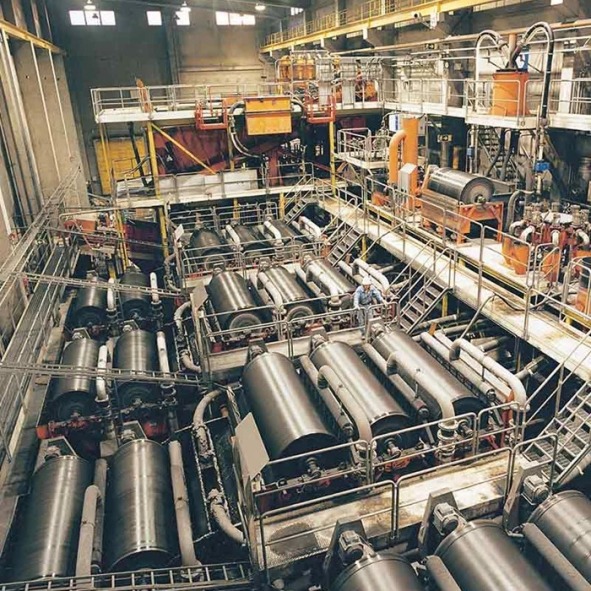

View of the ball mill manufactured by BonFan Company

A hydrocyclone separator

Gravity separation equipment, such as jigs, spirals, and shaking tables, utilizes differences in density to separate minerals from gangue materials, enabling the concentration of valuable minerals through gravitational forces.

Jigs function by use of water pulses that result in the differential acceleration and; therefore, deceleration of those particles that have different densities. They can either be continuous or of the batch type and are more efficient for rough to medium particle sizes. Screw are settling devices, gravity concentrators working on the principle of a flowing film which separates the particles based on the principle of density or size. It is easy to use, involve low costs in handling and provide suitable results for different particle sizes. Shaking tables include a deck that is slightly inclined in the direction of the axis of rotation with a riffled surface on which there is a film of water. Particles with higher densities move to the bottom of the deck and are collected at the end, while lighter particles are washed over the riffles and collected separately.

Gravity separation is particularly advantageous for its simplicity, cost-effectiveness, and ability to handle a wide range of particle sizes. The recent innovations are the creation of multi-stage jigs and new and improved spiral designs in a bid to enhance on the recovery rates and the concentrations of the mineral. Some advances have also been recorded concerning the shaking tables through the current use of automatic control systems and highly efficient riffle pattern designs that enhance the separation chances. This method is also economical for the environment since no chemicals are used in the process and therefore commonly used in many mining industries.

Gravity spiral separators

Magnetic separators are used to separate magnetic minerals from non-magnetic materials, providing an efficient method for the concentration of magnetic ores such as iron ore and magnetite. Magnetic separators are categorized into low-intensity and high-intensity devices. Low-intensity magnetic separators (LIMS) are used for ferromagnetic minerals like magnetite, while high-intensity magnetic separators (HIMS) are used for paramagnetic minerals. Some of them are drum magnetic separators, wet magnetic separators and dry magnetic separators. In drum separators there is a rotating drum inside which there is a permanent magnet that does not move. Wet magnetic separators are suitable with slurry and are more efficient for finer sizes of particles while dry magnetic separators are only appropriate for larger particles.

As for advantages, magnetic separation possesses high throughput, simplicity of operation, versatility as to the type and size of the material to be separated. Recent enhancements have been made on higher magnetic field strength and better method of separation. For instance, the application of rare earth magnets has improved efficiency of magnetic separators much higher. Besides, the design of automated control systems has been included as components of the premier magnetic separators, making them more accurate and efficient.

High-gradient magnetic separators (HGMS) are another advanced type, intended for the separation of fine and weakly magnetic particles that are likely to be missed in the course of the use of simple separator methods. The use of the matrix of stainless steel wool enables one to create very high magnetic gradients, and hence, increases the capture effectiveness of small paramagnetic particles. Such advances make magnetic separators a requirement in the extraction process in mines as they help in the efficiency of sorting of valuable minerals, and popularizing the natural conservation of mines by avoiding the use of chemical substances.

View of the low intensity magnetic separators

Flotation machines are used to separate minerals from gangue by selectively attaching hydrophobic particles to air bubbles, allowing for the recovery of valuable minerals in the form of froth concentrate. The major principle of the flotation process is based on the difference in the surface characteristics of the minerals. The agents like collectors, frothers and modifiers are added to the slurry to increase the hydrophobic property of the targeted minerals. Thus, xanthates and other collectors enhance the non-wettability of the mineral faces. Frothers enhance the formation of the froth layer on top of the flotation cell so that the floatable materials can be taken to the surface. These are the adjusting agents, coagulating agents or retarding agents, which help in controlling the relations between the particles and the reagents.

New generation flotation devices and reagents have been invented due to improvement in the strategies of flotation. Contemporary flotation cells are built to enable the greatest possibly collection of minute particles, which are usually difficult to separate. These cells normally contain the generators of the microbubbles which generate more of the small bubbles thus raising the chance of particle-bubble binding. Besides, an increase in the popularity of the column flotation is also noted. Column flotation cells are taller and have a smaller footprint compared to traditional mechanical cells, providing a more efficient separation process with higher concentrate grades and better recovery rates. This method is most applicable for the large and complicated ores and in enhancing the recovery of the fine particles from the concentrating machine.

Flotation techniques have also received the application of automation and process controls in flow rates of air, addition of reagents, and pulp density among others. This leads to enhanced results to be more constant as well as the recovered rates to be maximum which decreases the operational costs as well as increases the efficiency.

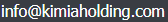

Installation of the flotation cell manufactured by BonFan Company

Thickeners and clarifiers are used to separate solids from liquids, allowing for the efficient removal of water from mineral slurries and the concentration of valuable minerals for further processing. There are high-rate thickeners and conventional type thickeners. High-rate thickeners have a higher design capacity and also use chemical coagulants/flocculants to enhance the rate of sedimentation of the fine particles. Primary clarifiers are commonly applied in the clarification process so as to obtain water out of slurry. The factors that distinguish the operations in thickeners and clarifiers include the feed well design, the type of rake mechanism, and the introduction of the flocculent to improve qualities of the solid-liquid separation.

The developments in thickener and clarifier designs have mainly concentrated on the feed well design so that the slurry fed into the clarifier can be well distributed and cause little turbulence within the clarifier tanks. Modern thickeners also incorporate high-efficiency rake mechanisms that provide gentle yet effective agitation, which aids in the densification of the underflow and prevents the buildup of settled solids.

In addition, new techniques, particularly those involving the design and implementation of sophisticated control systems, have made it possible to continually monitor as well as modify thickening and clarification processes in real time. These systems can allow the optimization of the flocculants amount, the speed of raking and the rate of the slurry feed so as to provide the required efficiency together with constant output quality. The addition of these technologies not only improve the separation efficiency but it also cuts the operational cost and energy usage. Also, new types of high density thickeners, with higher underflow densities, have been developed to increase concentration of mineral slurries. Such thickeners are most useful in arid zones as they ensure reduction of water consumption in the purification of minerals.

A view of a thickener installed at the mining site

Filters and dewatering equipment play a crucial role in mineral processing by removing moisture from mineral concentrates, thereby producing a dry final product suitable for transport and smelting. Such technologies are crucial in the improvement of the performance and overall reducing the cost of operating mineral processing plants. Based on the application and characteristics of dewatering types, the overall process methods can be broadly categorized into filtration, centrifugation and thermal drying, each with specific applications depending on the characteristics of the mineral slurry and the desired moisture content of the final product.

7-1. Filtration:

7-1-1. Pressure Filtration: Techniques like filter presses and pressure leaf filters in which a pressure is used to pump the slurry through a filter media resulting in a cake of dry solid leaving behind the liquid. The filter presses are best used for fine grained minerals and creates filter cakes of low moisture content.

7-1-2. Vacuum Filtration: Rotary drum filters and disk filters themselves develop a vacuum whereby the liquid passes through the filter medium but leaving solid particles behind them. Such filters are appropriate for slurries coarser within the range of a medium and the major application range is in the mining business since such filters can operates continuously.

7-2. Centrifugation:

Centrifuges utilize centrifugal force to accelerate the separation of solids and liquids. High-speed centrifuges are especially effective for fine particle slurries, achieving low moisture contents in the final product. They are used mostly in applications where high throughput as well as efficient means of dewatering are deemed necessary.

7-3. Thermal Drying:

If the amounts of water to be removed cannot be precipitated out by filtration or centrifuged down to the desired extent, thermal drying techniques like rotary dryer, fluidized bed dryer and spray dryer are used. These methods involve the application of heat in order to drive off the final traces of water from the mineral concentrates so that the end product is correctly dried.

Such technologies of dewatering are useful not only in upping the performance of Mineral processing but also in cutting on costs hence increasing the quality of the product.

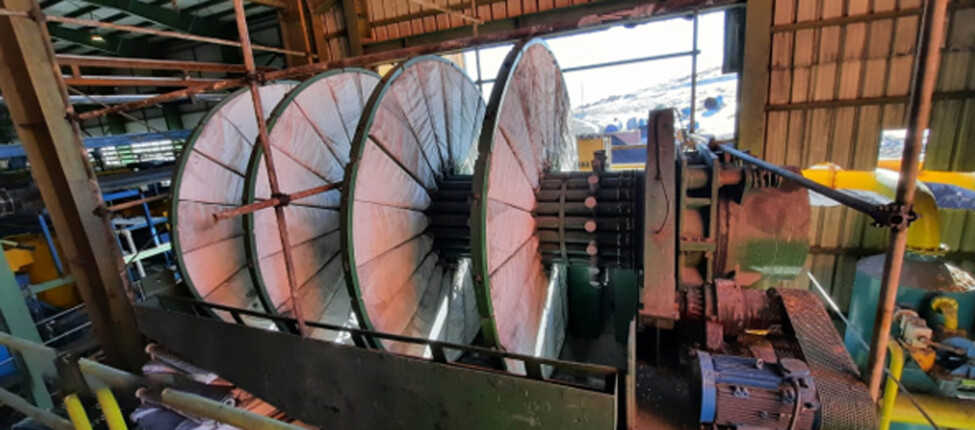

A view of the disc filter produced by BonFan Company, which has been installed at the processing plant of Kimia Mines Company

WE ARE KIMIA

Kimia Holding stands as a diversified conglomerate with a strong foothold in various sectors including mining and mineral resources, tourism services, livestock and poultry, agriculture, and foreign trade foreign trade in Iran and across the Middle East. However, it is within the realm of mining that Kimia Holding has truly distinguished itself, garnering recognition for its unwavering commitment to excellence and innovation.

CONTACT KIMIA

Our experts at Kimia Holding eagerly await your inquiries and are prepared to provide insightful answers or address any questions you may have. Should you require further details or wish to share your opinions, please don't hesitate to reach out. Your engagement is valuable to us.

Gravity spiral separators

Mineral processing equipment serves as the backbone of the mining industry, facilitating the refinement of valuable minerals from ore deposits. This crucial equipment encompasses a wide range of machinery and technologies designed to optimize the recovery of valuable minerals while minimizing waste and environmental impact. These are some of the essential facts that would define the economic and environmental efficiency of mining operations. Mineral processing being an aspect of mining can provide higher recovery of the valuable minerals and will reduce energy intake and the negative impact on the environment which is caused by the extraction and processing techniques. Let's delve deeper into the pivotal role that mineral processing equipment plays in the mining industry:

The Role of Mineral Processing Equipment in the Mining Industry

Once the ore is prepared, mineral processing equipment is used to separate valuable minerals from the gangue material. Techniques such as gravity separation, flotation, and magnetic separation are employed to concentrate valuable minerals and reduce the volume of waste material that needs to be handled. Gravity separation uses differences in density and basically comprises of jigs, shaking tables and spiral concentrators among others. Historically recognized as one of the most popular separation techniques, flotation implies using chemicals to make the target minerals water repellent so that they would float as bubbles to the surface of the collection trough. Another process is magnetic separation, which is pointed out when magnetic properties of minerals render it possible to separate the valuable minerals from non-magnetic gangue. Such operations as high-intensity magnetic separators and column flotation cells refine the efficiency and accuracy of these separations. By employing these techniques, mining operations can achieve higher concentrations of valuable minerals, thereby improving the overall economic viability and reducing the environmental impact of the mining activities.

2. Separation and Concentration

Mineral processing equipment is instrumental in preparing raw ore for subsequent processing steps. This includes crushing and grinding operations, where large chunks of ore are broken down into smaller particles to facilitate further processing. Crushing typically involves the use of jaw crushers or gyratory crushers, which apply compressive forces to break down the ore. Following crushing, grinding mills such as ball mills or SAG mills further reduce the particle size through mechanical forces, primarily impact and attrition. The intent of these operations is to free mineral particles from the surrounding gangue so that the separation process can be better served by the increased surface area. Minimizing the particle size of the product of the crushing stage therefore results in a better minerals recovery rate of the subsequent processes like flotation and leaching.

1. Ore Preparation

3. Dewatering and Moisture Control

After the minerals have been separated and concentrated, mineral processing equipment is used to remove excess moisture from the concentrate. Dewatering equipment such as thickeners, filters, and centrifuges are employed to produce a dry final product that is ready for transport and further processing. Thickeners on the other hand operates by putting the low density solids at the base while the clear water lavage, thus making the solids denser. Filters, including vacuum and pressure filters, use different mechanisms to separate solids from liquids. Whereas, the centrifuges use the principle of centrifugal force to filter and or segregate the fine particles from liquids. Effective dewatering also helps to decrease the price of transporting water away from the ore and increase the effectiveness of subsequent operations such as roasting or leaching. Additionally, managing moisture content is crucial to prevent issues like material handling problems and chemical reactions during transport and storage. Over the years, there has been a significant improvement in dewatering techniques meaning that water can now be reclaimed in higher quantities in the mining operations hence less water being used and the environment being protected.

4. Environmental Management

Environmental management is a critical aspect of modern mineral processing operations, aiming to minimize the ecological footprint of mining activities. Techniques such as gravity separation, flotation and magnetic separation are employed not only to concentrate valuable minerals but also to reduce the volume of waste material. Effective management of these residual by-products of ore processing must be given special attention to and properly disposed in order to avoid serious environmental contamination.

Metals extraction incorporates methods of tailings handling like paste thickening and dry stacking which help in eliminating the cases of tailing dams breach and the retention of less water. Also, because of its closed-loop water systems and the treatment of the process effluents which are infractions on the local water supply. Fine particle filtration systems and soil treatment programs are incorporated into the procedure to meet the environmental standards for air and ground purification in the regions where mineral processing occurs. By adopting sustainable practices and innovative technologies, the mining industry can achieve a balance between resource extraction and environmental stewardship.

5. Optimization of Operations

6. Safety and Worker Protection

Modern mineral processing equipment is equipped with advanced automation and control systems that optimize the efficiency and performance of mining operations. Real-time monitoring and data analysis enable operators to make informed decisions, adjust process parameters, and maximize the recovery of valuable minerals. Automation technologies such as programmable logic controllers (PLCs) and distributed control systems (DCS) integrate with sensors and software to continuously monitor variables like temperature, pressure, and chemical concentrations. The property implies that these systems are able to adapt to changes in the processing environment and operate without failure. Very recently, there has been a growing use of issues such as machine-learning and artificial intelligence (AI) in estimating equipment failures potential and also enhancing the process flow in industries. Through integration of these technologies the mining operations can experience marked increase in the improved throughput, energy consumptions as well as resource extrapolation; thus improving operating efficiency and net asset returns.

Ensuring the safety and well-being of workers is paramount in the mining industry. Mineral processing equipment is designed with safety features and protocols to minimize the risk of accidents and protect workers from hazardous conditions. Equipment is often fitted with emergency stop mechanisms, protective guards, and automated shutdown systems to prevent accidents. Instrumentation in the process industries enables the management of processes from a distance hence minimizing the effects of toxic sites on the operators.

Other features that add to worker safety include wearing of protective clothing and helmets as well as compulsive safety sessions. Additionally, better standard systems and methods of controlling prior to dust are used for high-quality air and limiting chances of respiratory health risks. In this view, it can be ascertained that the enhancement of safety through design, technology, and training can create a safer working space in the mining industries as well as decreases in workplace injuries and illnesses.

In conclusion, mineral processing equipment is the backbone of the mining industry, facilitating the efficient extraction and refinement of valuable minerals. The comprehensive array of equipment, from crushers and grinders to flotation machines and dewatering systems, ensures the effective preparation, separation, concentration, and handling of mineral resources. Improved technology in areas of automation as well as control systems have greatly improved the efficiency safety and environmental friendly exploitation of mines. In aspects like monitoring of the process, decision making and availability of equipment, real-time and data based decision making enhances operational efficiency, reduction of time lost and high recovery levels of the sought after minerals. Technological measures in the management of environment include handling and disposal of tailings and the use of closed circuits especially in water usage reduces the impact on ecology. Measures that are engineered into tools or instruments designed in the equipment ensure that the workers would not be subjected to poisonous articles hence making the workplace safer. There is a great potential for future advancements in mineral processing hence, indicating that the efficiency in the utilization of the resources, the operational efficiency and environmental friendly ways of working will improve in the future. By adopting these advanced technologies and sustainable practices, the mining industry can achieve a balance between economic growth and environmental responsibility, ensuring its long-term viability and positive contribution to global resource management.

Conclusion

Resources

1. Kelly, E. G.; Spottiswood, D. J.; Introduction to Mineral Processing, John Wiley & Sons, 1982.

2. Fuerstenau, M. C.; Han, K. N.; Principles of Mineral Processing, Society for Mining, Metallurgy and Exploration, 2003.

3. Hudson-Edwards, K. A.; Jamieson, H.; Lottermoser, B. G.; "Mine Wastes: Past, Present, Future", Elements, 76(6), pp. 375-80, 2011.

4. Bhattacharya, J.; Design and Selection of Bulk Material Handling Equipment and Systems: Mining, Mineral Processing, Port, Plant and Excavation Engineering, Vol. 1, WidePub, 2012.

5. Wills, B. A.; Finch, J. A.; Wills' Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, Butterworth-Heinemann, 2015.

Written by Bon Fan Company (BFC)

A knowledge-based enterprise leveraging cutting-edge technical knowledge and the invaluable experience of seasoned industry professionals. The company excels in the design, manufacturing, and installation of both lightweight and heavy equipment, primarily for mineral processing industries. Among its activities are the design and construction of ball mills, rod mills, flotation cells, thickeners, drum filters, disc filters, dryers, melting furnaces, conditioners, various types of tanks, and separators. Additionally, BFC is known for its innovation and commitment to sustainable practices.